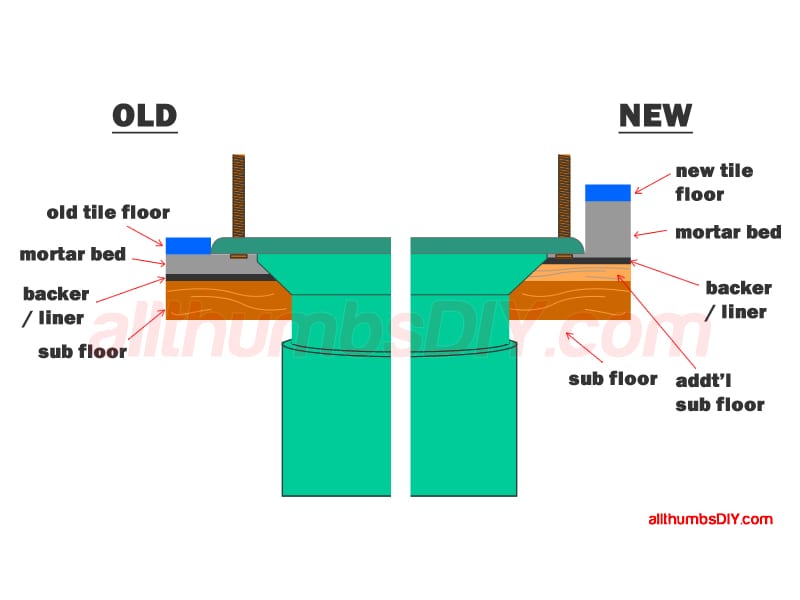

The reason being is because the toilet recesses into the flange when fully installed but when the flange sits even or below the floor the toilet can t properly recess into the flange.

Toilet flange below floor level.

It has to sit evenly on top of the finished floor.

In a typical toilet installation the floor flange that sits inside the drain opening below the toilet should be positioned so that its bottom surface rests flush against the finished floor or no more than 1 4 inch above or below the floor this ensures that the flange makes a watertight seal against the wax ring that fits between the drain opening and drain outlet horn on the underside of.

Large bolts thread up through.

To get the necessary clearance from the floor you can add a toilet flange extender which is quick and easy to install.

The perfect height for the toilet flange is to be the same level as the finished floor.

Flange extenders are commonly sold in 1 4 inch and 1 2 inch sizes to raise the height of the existing flange 1 4 or 1 2 inch.

Clean the top of the.

When the toilet was removed the toilet wax ring was still in its original shape.

When installing the toilet flange you need to check that it s the correct height and is also perfectly level.

A sign that the wax ring was not sealing the toilet from sewer gases or preventing water escaping from under the base of the toilet.

Here you can see the results of a toilet having been installed on a toilet flange that is below the floor level.

If your flange sits even or below the floor then it s wrong.

My flange sat about 1 8 below floor level i took two 1 4 flange spacers and siliconed them together.

This is very important.

Purchase a toilet flange extension ring thick enough to raise the toilet mounting surface so that it s approximately 1 4 inch above the level of the finished tile floor.

If the toilet flange is at the incorrect height it will cause problems with the toilet connecting onto the plumbing.

A toilet drain flange can sit above or below the finished floor level.

Here s what i did.

I took normal wax ring and put it on the metal flange.

Thanks for this idea.

I put heated it up by running in hot water wrapped in this plastic bag then pushed down on it slowy and evenly until it was about 1 16 in.